| S KORONKA {MANUFACTURING} LTD |

|---|---|

|

|

| S KORONKA {MANUFACTURING} LTD |

|---|---|

|

|

7 000 LITRE GAS OIL UNIT ::

Site - RAF Lakenheath. Use - Stand By Generator. |

|

|

8 000 LITRE GAS OIL UNITS ::

Site - British Telecom - Bracknell. Use - Stand By Generator. |

| 27 000 LITRE DERV UNIT, FITTED VEHICLE PUMPING SYSTEM:: |

|

|

|

Site - Weeford, West Midlands. Use - Refuelling Vehicles. |

|

TOTAL SECURITY |

|

|

TOTAL SECURITY |

|

30 000 LITRE GAS OIL UNIT FITTED TWINSET ::

Site - North Allerton. Use -Burners in Coating Plant. |

|

| CLOSE UP's | ||

|

|

|

| Close up of Twin Set L/H Side. | Close up of control panel. | Close up of Twin set R/H Side. |

| 35 000 LITRE BULK TANK FOR SAUGHTON HOUSE DATA CENTRE, EDINBURGH - DIESELEC GENERATORS C/W TWIN TWINSET PUMPING SYSTEM:: |

|

|

|

|

| Built in twinsets are designed with each pump being fitted with its own inlet and isolation valve to ensure continuity of supply in the event of pump failure. A non return valve followed by an isolation valve are fitted on discharge and then piped together to form common discharge. All pipe work is clamped to the cabinet floor. Pipe work diameter is sized to suit the application/pump. Test ports are fitted each side of pump and a return line via a lock shield valve to top of tank to allow for commissioning of the pumps. Each pump is fitted with a pressure gauge on discharge a compound gauge on the suction side. Each set has its own bowl filters fitted prior to the pump to protect against dirt. |

| 38 000 LITRE BITUMEN UNIT FITTED PUMP, DISPENCING SYSTEM WITH HEATER AND MIXER PADDLES:: |

|

|

|

Site - Dumfries Council, Lockerbie. Use - Bitumen for Road Repairs. |

|

DETAIL |

|

|

DETAIL |

|

| FUEL POLISHING SYSTEMS |

| 52 000 LITRE BULK TANK FOR DATA CENTRE C/W FUEL POLISHING SYSTEM:: |

|

|

|

FUEL POLISHING SYSTEM SPECIFICATION |

| Hydrocarbon Filter Vessels remove both sediment and free water from the fuel. With options of 30um, 10um and 5um |

|

DETAIL |

|

|

SPEC SHEET ON FILTER ASSEMBLYS PDF Spec Sheet of Filter {88KB}

O and M MANUAL ON FILTER ASSEMBLYS PDF Spec Sheet of Filter {724KB} |

| OTHER FUEL POLISHING SYSTEMS:: |

|

|

|

DETAIL:: |

|

|

SPEC SHEET ON FILTER ASSEMBLY PDF Spec Sheet of Filter {151KB}

|

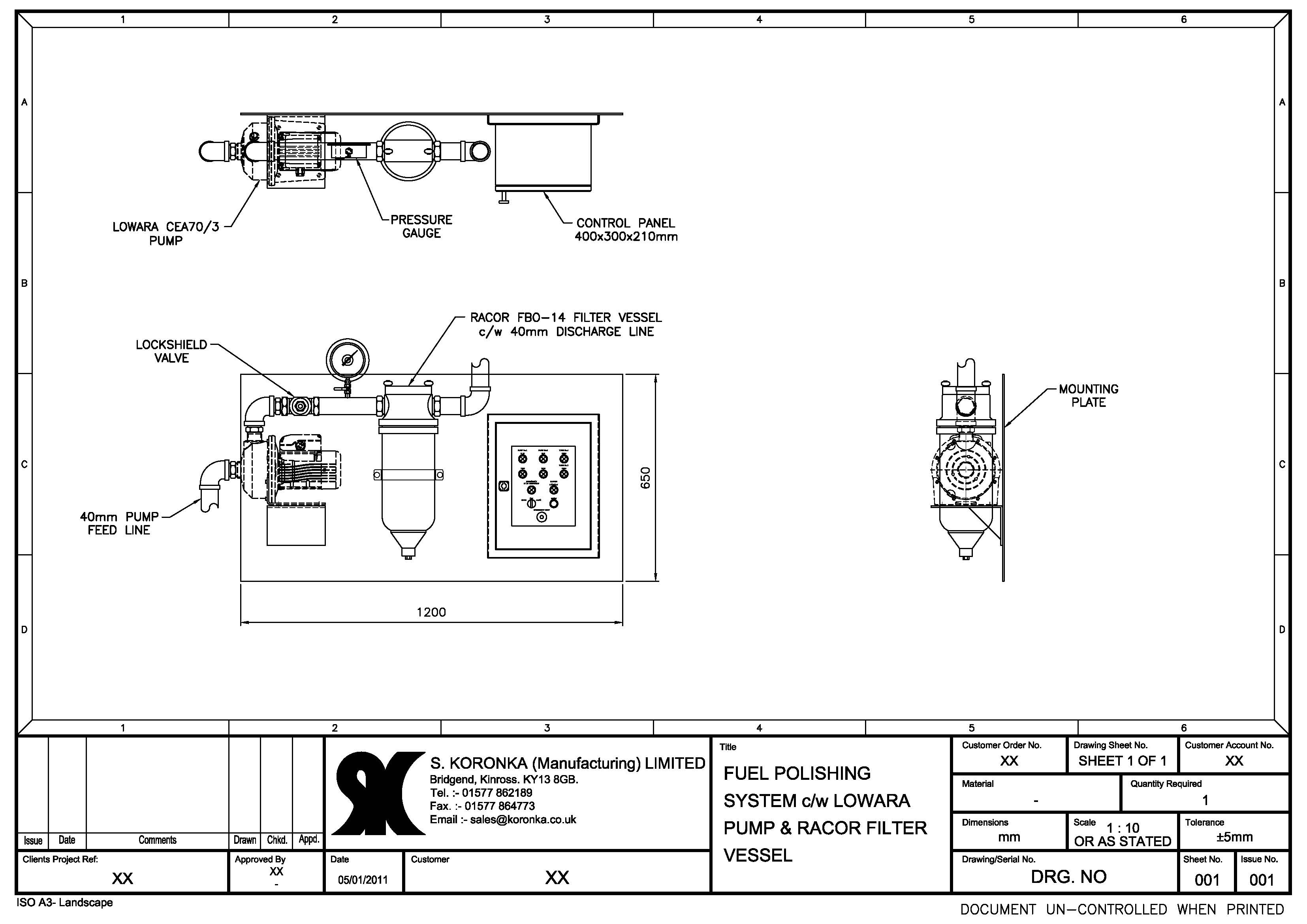

| FUEL POLISHING SYSTEMS FOR EXISTING TANKS:: |

|

|

PDF DRAWING OF ABOVE SYSTEM PDF Drawing of Fuel Polishing System on Mounting Plate.{165KB}

|

| 89 000 LITRE BULK TANK FOR VICTORIA HOSPITAL, GLASGOW:: |

|

|

|

DETAIL |

|

|

DETAIL |

|

|

90 000 LITRE GAS OIL UNITS ::

Site - Rolls Royce Skipton. Use - 30 sec Oil for Boiler. |

|

SECURITY CABINET

|

|

|

This heavy oil tank is fitted with 3 removable core immersion heaters to maintain the oil at 20 degrees. The oil is then sucked through an

outflow heater where it is lifted to 40 degrees for pumping. When the oil reaches the plant room a line heater again lifts oil to 60 degrees suitable

for burning. This system is on a ring main with between 30% & 50% of the oil returning to the bulk tank where it is piped back into the out flow heater

to save being reheated.

This type of unit comes completely wired and ready for use. The tank can be off loaded and powered up immediately therefore minimising on costly onsite installation work. |